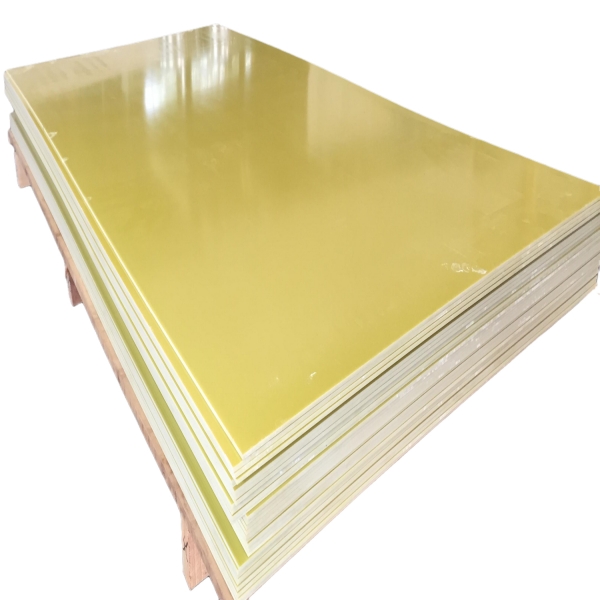

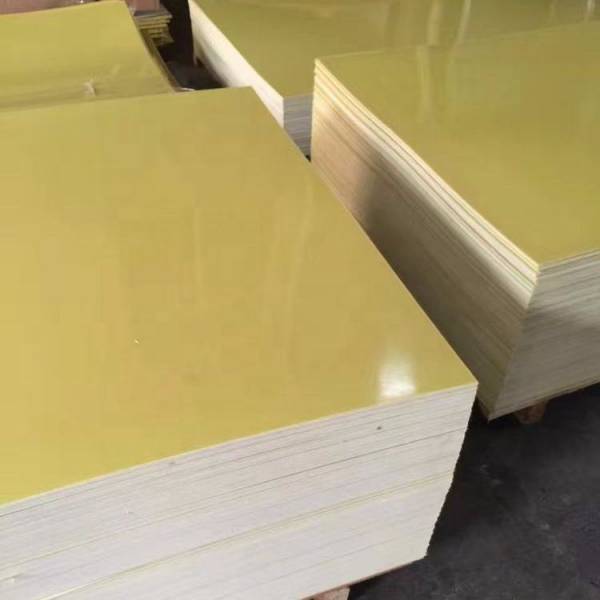

3240 Epoxy Phenolic Glass Lesela Base Tigid Laminated Sheet

Litlhoko tsa Tekheniki

1.1Ponahalo:Bokaholimo ba lakane bo lokela ho ba bo bataletseng le bo boreleli, bo se nang lipululana tsa moea, makukuno kapa mapetso 'me bo se na liphoso tse ling tse nyane tse kang mengoapo, matheba, jj. Moeli oa lakane o lokela ho ba o hloekileng 'me o se na matheba le mapetso. 'Mala o lokela ho tšoana hantle, empa matheba a 'maloa aa lumelloa.

1.2Tekanyo le e lumelletsoengmamello

1.2.1 Bophara le Bolelele ba Maqephe

| Bophara le Bolelele (mm) | Mamello (mm) |

| >970~3000 | +/-25 |

1.2.2 Botenya le mamello e tloaelehileng

| Botenya bo ikgethang (mm) | Mamello (mm) | Botenya bo ikgethang (mm) | Mamello (mm) |

| 0.5 0.6 0.8 1.0 1.2 1.6 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.12 +/-0.13 +/-0.16 +/-0.18 +/-0.20 +/-0.24 +/-0.28 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 80 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.95 +/-2.10 +/-2.30 +/-2.45 +/-2.50 +/-2.80 |

| Litlhaloso: Bakeng sa botenya bo seng ba mabitso bo sa thathamisitsoeng tafoleng ena, ho kheloha ho tla tšoana le ha botenya bo bong bo latelang bo boholo. | |||

1.3Ho Kobeha ho Fapoha

| Botenya (mm) | Ho Kobeha ho Fapoha | |

| 1000mm (bolelele ba 'Musi) (mm) | 500mm (bolelele ba 'Musi) (mm) | |

| 3.0~6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 | ≤2.5 ≤2.0 ≤1.5 |

1.4Ts'ebetso ea mechini:Maqephe a lokela ho se be le mapetso, dikgeo le masalla ha ho sebediswa machining a kang ho saga, ho tjheka, ho roka le ho sila.

1.5Thepa ea 'mele, ea mechini le ea motlakase

| Tjhe. | Matlo | Yuniti | Boleng bo tloaelehileng | Boleng bo tloaelehileng |

| 1 | Botenya | g/cm3 | 1.7~1.95 | 1.94 |

| 2 | Ho monya metsi (letlapa la 2mm) | mg | ≤20 | 5.7 |

| 3 | Matla a ho tenyetseha, a otlolohileng ho laminations | MPa | ≥340 | 417 |

| 4 | Matla a tshusumetso (Charpy, notch) | kJ/m2 | ≥30 | 50 |

| 5 | Ntho ea ho qhala ha dielectric 50Hz | --- | ≤5.5 | 4.48 |

| 6 | Phetoho ea dielectric 50Hz | --- | ≤0.04 | 0.02 |

| 7 | Khanyetso ea ho thibela ho ruruha (Kamora lihora tse 24 ka metsing) | Ω | ≥5.0 x108 | 4.9 x109 |

| 8 | Matla a dieleketeroliki, a otlolohileng ho laminations ka oli ea transformer ho 90℃+/-2℃, lakane ea 1mm | kV/mm | ≥14.2 | 16.8 |

| 9 | Motlakase oa ho senyeha, o tsamaellanang le laminations oli ea transformer ho 90℃+/-2℃ | kV | ≥35 | 38 |

Ho paka, ho tsamaisa le ho boloka

Maqephe a lokela ho bolokoa sebakeng seo mocheso o seng hodimo ho 40℃, mme a bewe ka ho rapama hodima poleiti e bolelele ba 50mm kapa ho feta. Boloka hole le mollo, mocheso (sesebelisoa sa ho futhumatsa) le letsatsi le tobileng. Nako ya polokelo ya maqephe ke dikgwedi tse 18 ho tloha ka letsatsi leo a tswang fekthering ka lona. Haeba nako ya polokelo e feta dikgwedi tse 18, sehlahiswa se ka sebediswa hape kamora ho lekoa ho netefatsa hore se a tshwaneleha.

Litlhaloso le Litlhokomelo bakeng sa Kopo

Lebelo le phahameng le botebo bo bonyenyane ba ho seha g li tla sebelisoa ha ho etsoa machining ka lebaka la ho tsamaisoa ha mocheso o fokolang oa maqephe.

Ho sebetsa ka mochini le ho seha sehlahisoa sena ho tla ntša lerōle le mosi o mongata. Mehato e loketseng e lokela ho nkoa ho netefatsa hore maemo a lerōle a ka har'a meeli e amohelehang nakong ea ts'ebetso. Ho eletsoa hore moea o kenang ka har'a mosi o tsoang sebakeng seo le ho sebelisa maske ea lerōle/likaroloana.

Maqephe a ka tlas'a mongobo ka mor'a ho etsoa ka mochini, ho khothaletsoa ho roala ka ho thibela ho ruruha.

Lisebelisoa tsa Tlhahiso

Sephutheloana sa Lipampiri tse Laminated