Leqephe la ho thibela mocheso le bōpiloeng ka D370 SMC

Leqephe la ho kenya thepa le bopilweng ka D370 SMC ke mofuta oa leqephe la ho kenya thepa le thata le thermosetting. Le entsoe ka SMC ka har'a hlobo tlas'a mocheso o phahameng le khatello e phahameng. Le na le setifikeiti sa UL 'me le fetile teko ea REACH le RoHS, jj. Le boetse le bitsoa leqephe la SMC, boto ea ho kenya thepa ea SMC, jj.

SMC ke mofuta oa motsoako oa ho bopa lakane o nang le faeba ea khalase e matlafalitsoeng ka resin ea polyester e sa koaheloang, e tletseng sethibela-mollo le ntho e 'ngoe e tlatsang.

Maqephe a SMC a na le matla a phahameng a mechini, matla a dielectric, khanyetso e ntle ea malakabe, khanyetso ea ho latela, khanyetso ea arc le motlakase o phahameng oa ho mamella, hammoho le ho monya metsi a tlase, mamello e tsitsitseng ea litekanyo le ho kheloha ho honyenyane. Maqephe a SMC a sebelisetsoa ho etsa mefuta eohle ea liboto tsa ho thibela mocheso ka li-switch gear tse phahameng kapa tse tlase. E ka boela ea sebelisoa ho sebetsana le likarolo tse ling tsa sebopeho sa ho thibela mocheso.

Botenya: 2.0mm ~ 60mm

Boholo ba lakane: 580mm * 850mm, 1000mm * 2000mm, 1300mm * 2000mm, 1500mm * 2000mm kapa boholo bo bong bo buisanoeng

SMC

DMC

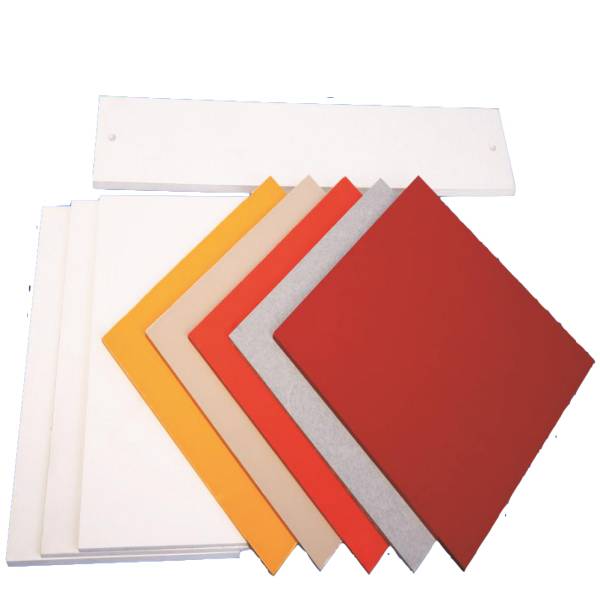

Maqephe a SMC Ka mebala e fapaneng

Maqephe a SMC

Litlhoko tsa Tekheniki

Ponahalo

Bokaholimo ba eona bo lokela ho ba bataletse ebile bo boreleli, bo se na matheba, matheba le tšenyo e totobetseng ea mechine. 'Mala oa bokaholimo ba eona o lokela ho ba o ts'oanang, o se na faeba e totobetseng e pepeneneng. O se na tšilafalo e totobetseng, litšila le masoba a totobetseng. O se na ho arohana le ho petsoha mathōkong a eona. Haeba ho na le liphoso holim'a sehlahisoa, li ka petloa. Molora o mongata o tlameha ho hloekisoa.

The bpherekano e fellangYuniti: mm

| Tse khethehileng | Tekanyo ea sebopeho | Botenya bo ikgethang S | Ho kobeha ha ho kgeloha | Botenya bo ikgethang S | Ho kobeha ha ho kgeloha | Botenya bo ikgethang S | Ho kobeha ha ho kgeloha |

| Leqephe la D370 SMC | Bolelele ba mahlakore ohle ≤500 | 3≤S<5 | ≤8 | 5≤S<10 | ≤5 | ≥10 | ≤4 |

| Bolelele ba lehlakore lefe kapa lefe | 3≤S<5 | ≤12 | 5≤S<10 | ≤8 | ≥10 | ≤6 | |

| 500 ho isa ho 1000 | |||||||

| Bolelele ba lehlakore lefe kapa lefe ≥1000 | 3≤S<5 | ≤20 | 5≤S<10 | ≤15 | ≥10 | ≤10 |

Litlhoko tsa tshebetso

Thepa ea 'mele, ea mechini le ea motlakase bakeng sa maqephe a SMC

| Matlo | Yuniti | Boleng bo tloaelehileng | Boleng bo tloaelehileng | Mokhoa oa teko | ||

| Botenya | g/cm3 | 1.65—1.95 | 1.79 | GB/T1033.1-2008 | ||

| Bothata ba Barcol | - | ≥ 55 | 60 | ASTM D2583-07 | ||

| Ho monya metsi, botenya ba 3mm | % | ≤0.2 | 0.13 | GB/T1034-2008 | ||

| Matla a ho tenyetseha, a otlolohileng ho laminations | Bolelele | MPa | ≥170

| 243 | GB/T1449-2005 | |

| Tsela e tšekaletseng | ≥150 | 240 | ||||

| Matla a Tšusumetso, a tsamaellanang le li-lamination (Charpy, e sa ngoloang) | KJ/m2 | ≥60 | 165 | GB/T1447-2005 | ||

| Matla a tšepe | MPa | ≥55 | 143 | GB/T1447-2005 | ||

| Modulus ea ho tenyetseha ha tensile | MPa | ≥9000 | 1.48 x 104 | |||

| Ho nyenyefatsa ho bopa | % | - | 0.07 | ISO2577:2007 | ||

| Matla a ho hatella (a otlolohileng ho a laminations) | MPa | ≥ 150 | 195 | GB/T1448-2005 | ||

| Modulus e hatellang | MPa | - | 8300 | |||

| Mocheso oa ho kheloha ha mocheso tlas'a mojaro (T)ff1.8) | ℃ | ≥190 | >240 | GB/T1634.2-2004 | ||

| Coefficient ea katoloso ea mocheso oa liner (20℃ - 40℃) | 10-6/K | ≤18 | 16 | ISO11359-2-1999 | ||

| Matla a motlakase (ka oli ea transformer ea 25# ho 23℃+/-2℃, teko ea nako e khuts'oane, Φ25mm/Φ75mm, electrode ea cylindrical) | KV/mm | ≥12 | 15.3 | GB/T1408.1-2006 | ||

| Motlakase oa ho senyeha (o tsamaellana le li-lamination, ka oli ea transformer ea 25# ho 23℃+/-2℃, teko ea mohato ka mohato ea metsotso ea 20, Φ130mm/Φ130mm, electrode ea poleiti) | KV | ≥25 | >100 | GB/T1408.1-2006 | ||

| Ho hanyetsa molumo | Ω.m | ≥1.0 x 1012 | 3.9 x 1012 | GB/T1408.1-2006 | ||

| Ho hanyetsa holim'a metsi | Ω | ≥1.0 x 1012 | 2.6 x 1012 | |||

| Tekanyo e amanang le tumello (1MHz) | - | ≤ 4.8 | 4.54 | GB/T1409-2006 | ||

| Ntho ea ho qhalana ha dielectric (1MHz) | - | ≤ 0.06 | 9.05 x 10-3 | |||

| Khanyetso ea Arc | s | ≥180 | 181 | GB/T1411-2002 | ||

| Khanyetso ea ho latela | CTI

| V | ≥600 | 600 Ho feta tekano | GB/T1411-2002

| |

| PTI | ≥600 | 600 | ||||

| Khanyetso ea ho thibela ho ruruha | Boemong bo tloaelehileng | Ω | ≥1.0 x 1013 | 3.0 x 1014 | GB/T10064-2006 | |

| Kamora lihora tse 24 ka metsing | ≥1.0 x 1012 | 2.5 x 1013 | ||||

| Ho cha | Sehlopha | V-0 | V-0 | UL94-2010 | ||

| Letšoao la oksijene | ℃ | ≥ 22 | 32.1 | GB/T2406.1 | ||

| Teko ea terata e khanyang | ℃ | >850 | 960 | IEC61800-5-1 | ||

Mamella motlakase

| Botenya bo ikgethang (mm) | 3 | 4 | 5~6 | >6 |

| Ema ka matla moeeng ka motsotso o le mong KV | ≥25 | ≥33 | ≥42 | >48 |

Tlhahlobo, Letšoao, Sephutheloana le Polokelo

1. Sehlopha se seng le se seng se lokela ho lekoa pele se romelloa.

2. Ho ya ka ditlhoko tsa bareki, mokgwa wa teko wa ho mamella motlakase o ka buisanwa ho ya ka maqephe kapa dibopeho.

3. E pakiloe ka lebokose la khateboto phaleteng. Boima ba eona ha bo fete 500kg phaleteng ka 'ngoe.

4. Masela a lokela ho bolokoa sebakeng seo mocheso o sa feteng 40℃, 'me a behoe ka ho otloloha holim'a poleiti e bolelele ba 50mm kapa ho feta. Boloka hole le mollo, mocheso (sesebelisoa sa ho futhumatsa) le khanya ea letsatsi e tobileng. Nako ea polokelo ea masela ke likhoeli tse 18 ho tloha ka letsatsi leo a tsoang fekthering ka lona. Haeba nako ea polokelo e feta likhoeli tse 18, sehlahisoa se ka sebelisoa ka mor'a hore se hlahlojoe hore sea tšoaneleha.

5. Ba bang ba tla dumellana le dipehelo tsa GB/T1305-1985,Melao e akaretsang bakeng sa tlhahlobo, matšoao, ho paka, ho tsamaisa le ho boloka thepa ea thermosetting ea insulation.

Setifikeiti