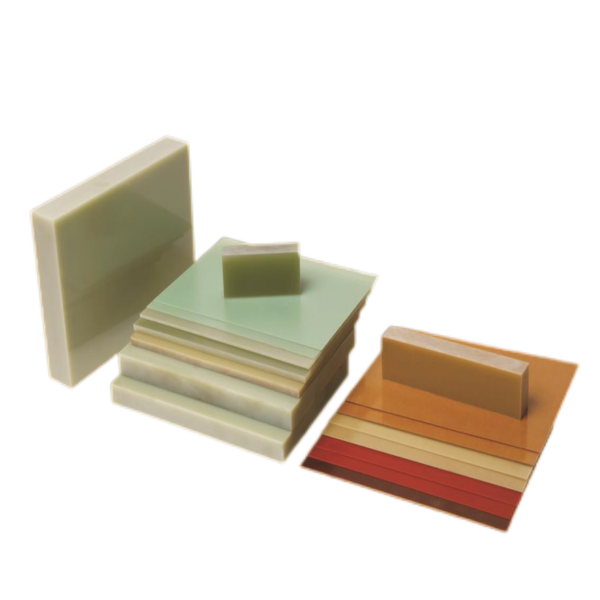

Lesela la Khalase la DF350A le Fetotsoeng la Diphenyl Ether le Tiileng le nang le Laminated

DF350Ae entsoe ka lesela la khalase le lohiloeng le tšetsoeng resin ea thermosetting ea diphenyl ether e fetotsoeng, e laminated tlas'a mocheso o phahameng le khatello. Lesela la khalase le lohiloeng le lokela ho se be le alkali 'me le hloekisoe ke KH560.

DF350A e na le kganyetso e ntle ya mocheso, e na le thepa e ntle ya mechine le dielectric, e loketse tshebediso dienjining tsa motlakase tsa sehlopha sa H kapa disebedisweng tsa motlakase e le dikarolo kapa dikarolo tsa sebopeho sa ho kwahela mocheso. E sebediswa haholoholo dienjining tsena tsa motlakase kapa disebedisweng tsa motlakase tse hlokang tshebetso e phahameng ya mechini tlasa kgatello ya boemo ba mocheso.

Botenya bo fumanehang:0.5mm ~ 200mm

Boholo ba lakane bo fumanehang:

1500mm*3000mm、1220mm*3000mm、1020mm*2040mm,1220mm*2440mm、1000mm*2000mm le boholo bo bong bo reriloeng.

Botenya bo Ikhethileng le Mamello e Lumelloang (mm)

| Botenya bo ikgethang | Ho kheloha | Botenya bo ikgethang | Ho kheloha | Botenya bo ikgethang | Ho kheloha |

| 0.5 | +/-0.15 | 3 | +/-0.37 | 16 | +/-1.12 |

| 0.6 | +/-0.15 | 4 | +/-0.45 | 20 | +/-1.30 |

| 0.8 | +/-0.18 | 5 | +/-0.52 | 25 | +/-1.50 |

| 1 | +/-0.18 | 6 | +/-0.60 | 30 | +/-1.70 |

| 1.2 | +/-0.21 | 8 | +/-0.72 | 35 | +/-1.95 |

| 1.5 | +/-0.25 | 10 | +/-0.94 | 40 | +/-2.10 |

| 2 | +/-0.30 | 12 | +/-0.94 | 45 | +/-2.45 |

| 2.5 | +/-0.33 | 14 | +/-1.02 | 50 | +/-2.60 |

Ho Kobeha Phapang (mm)

| Botenya | Ho kobeha ha ho kgeloha | |

| 1000 (Bolelele ba 'Musi) | 500 (Bolelele ba 'Musi) | |

| 3.0~6.0 | ≤10 | ≤2.5 |

| 6.1~8.0 | ≤8 | ≤2.0 |

| >8.0 | ≤6 | ≤1.5 |

Thepa ea 'Mele, ea Mekaniki le ea Dielectric

| Tjhe. | Matlo | Yuniti | Boleng bo tloaelehileng | Boleng bo tloaelehileng | ||

| 1 | Botenya | g/cm3 | 1.70~1.95 | 1.9 | ||

| 2 | Matla a ho kokobela, a otlolohileng ho laminations (Bolelele) | Boemong bo tloaelehileng | MPa | ≥400 | 540 | |

| 180℃+/-2℃ | ≥200 | 400 | ||||

| 3 | Matla a tšusumetso (Charpy, notch, bolelele) | kJ/m2 | ≥37 | 50 | ||

| 4 | Matla a khomaretso/tlamo | N | ≥5000 | 6900 | ||

| 5 | Ho monya metsi | mg | Sheba tafole e latelang | 11.8 | ||

| 6 | Khanyetso ea ho thibela ho ruruha, e tsamaellanang le li-lamination | Boemong bo tloaelehileng | MΩ | ≥1.0 x 106 | 5.3 x 107 | |

| Kamora lihora tse 24 ka metsing | ≥1.0 x 102 | 3.8 x 104 | ||||

| 7 | Ntho ea ho qhala ha dielectric 1MHz | -- | ≤0.05 | 1.03 x 10-2 | ||

| 8 | 1MHz e sa fetoheng ea dielectric | -- | ≤5.5 | 4.7 | ||

| 9 | Voltage ea ho senyeha, e tsamaellanang le li-lamination (ka oli ea transformer ho 90℃+/-2℃) | kV | ≥30 | 35 | ||

| 10 | Matla a Dielectric, a otlolohileng ho laminations (ka oli ea transformer ho 90℃ +/-2℃), lakane ea 2mm | MV/m | ≥11.8 | 18 | ||

Ho Monya Metsi

| Botenya bo tloaelehileng ba disampole tsa liteko (mm) | Ho monya metsi (mg) | Botenya bo tloaelehileng ba disampole tsa liteko (mm) | Ho monya metsi (mg) | Botenya bo tloaelehileng ba disampole tsa liteko (mm) | Ho monya metsi (mg) |

| 0.5 | ≤17 | 2.5 | ≤21 | 12 | ≤38 |

| 0.8 | ≤18 | 3.0 | ≤22 | 16 | ≤46 |

| 1.0 | ≤18 | 5.0 | ≤25 | 20 | ≤52 |

| 1.6 | ≤19 | 8.0 | ≤31 | 25 | ≤61 |

| 2.0 | ≤20 | 10 | ≤34 | Sheba Litlhaloso 2 | ≤73 |

| Litlhaloso:1) Haeba karolelano e baliloeng ea botenya bo lekantsoeng e pakeng tsa botenya bo habeli bo boletsoeng tafoleng ena, boleng bo tla fumanoa ka ho kengoa ha lintlha. Haeba karolelano ea botenya bo lekantsoeng e le ka tlase ho 0.5mm, li-vales li ke ke tsa feta 17mg. Haeba karolelano ea botenya bo lekantsoeng e le ka holimo ho 25mm, boleng bo ke ke ba feta 61mg.2) Haeba botenya bo tloaelehileng bo feta 25mm, bo tla etsoa ka mochini ho fihlela ho 22.5mm ka lehlakoreng le leng. Lehlakore le lekantsoeng le lokela ho ba boreleli. | |||||

Ho paka le ho boloka

Maqephe a lokela ho bolokoa sebakeng seo mocheso o sa feteng 40℃, 'me a behoe ka ho rapama holim'a poleiti e bolelele ba 50mm kapa ho feta.

Boloka hole le mollo, mocheso (sesebelisoa sa ho futhumatsa) le khanya ea letsatsi e tobileng. Nako ea polokelo ea masela ke likhoeli tse 18 ho tloha ka letsatsi leo a tsoang fekthering. Haeba nako ea polokelo e feta likhoeli tse 18, sehlahisoa se ka boela sa sebelisoa kamora hore se hlahlojoe hore se tšoanelehe.

Litlhaloso le Litlhokomelo bakeng sa Kopo

Lebelo le phahameng le botebo bo bonyenyane ba ho seha di tla sebediswa ha ho sebetswa ka lebaka la ho kganna ha mocheso o fokolang wa maqephe.

Ho sebetsa ka mochini le ho seha sehlahisoa sena ho tla ntša lerōle le mosi o mongata. Mehato e loketseng e lokela ho nkoa ho netefatsa hore maemo a lerōle a ka har'a meeli e amohelehang nakong ea ts'ebetso. Ho eletsoa hore moea o kenang ka har'a mosi o tsoang sebakeng seo le ho sebelisa limaske tse loketseng tsa lerōle/likaroloana.

Maqephe a ka tlas'a mongobo ka mor'a ho etsoa ka mochini, ho khothaletsoa ho roala ka ho thibela ho ruruha.