GPO-3 (UPGM203) Mat ea Khalase ea Polyester e sa Tlatsoang Laminated Mat

Leqephe le Entsoeng ka GPO-3 (leo hape le bitswang GPO3, UPGM203) le na le materase a khalase a se nang alkali a kentsweng mme a tlangwa ka resin ya polyester e sa tlalang, mme a laminated tlasa mocheso o phahameng le kgatello e phahameng hlobo. E na le bokgoni bo botle ba ho sebetsa, matla a phahameng a mechini, thepa e ntle ya dielectric, kganyetso e ntle ya ho latela e thibelang le kganyetso ya arc. E na le setifikeiti sa UL mme e fetile teko ya REACH le RoHS, jj. E boetse e bitswa GPO-3 kapa lakane ya GPO3, GPO-3 kapa boto ya ho kenya disele ya GPO3.

E sebetsa bakeng sa ho etsa likarolo kapa likarolo tsa sebopeho sa insulation le tse tšehetsang li-motor tsa motlakase tsa sehlopha sa F, li-transformer, li-switch gear, li-circuit breaker le lisebelisoa tsa motlakase. UPGM e ka bōptjoa ka ho toba hore e be liprofaele tse fapaneng kapa likarolo tsa sebopeho sa insulation.

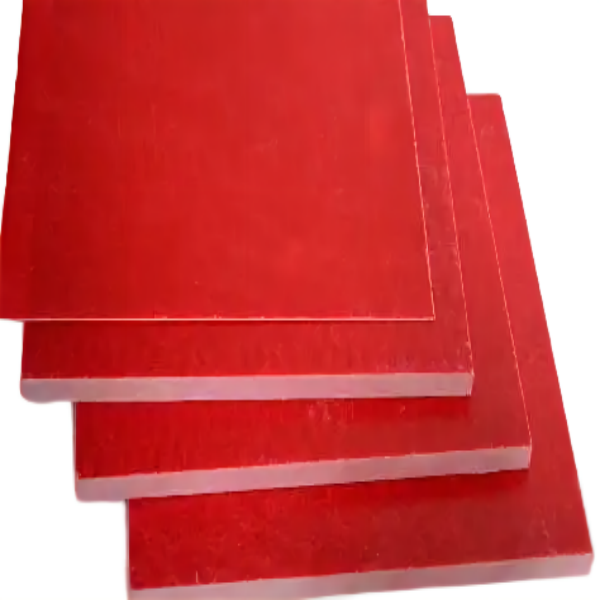

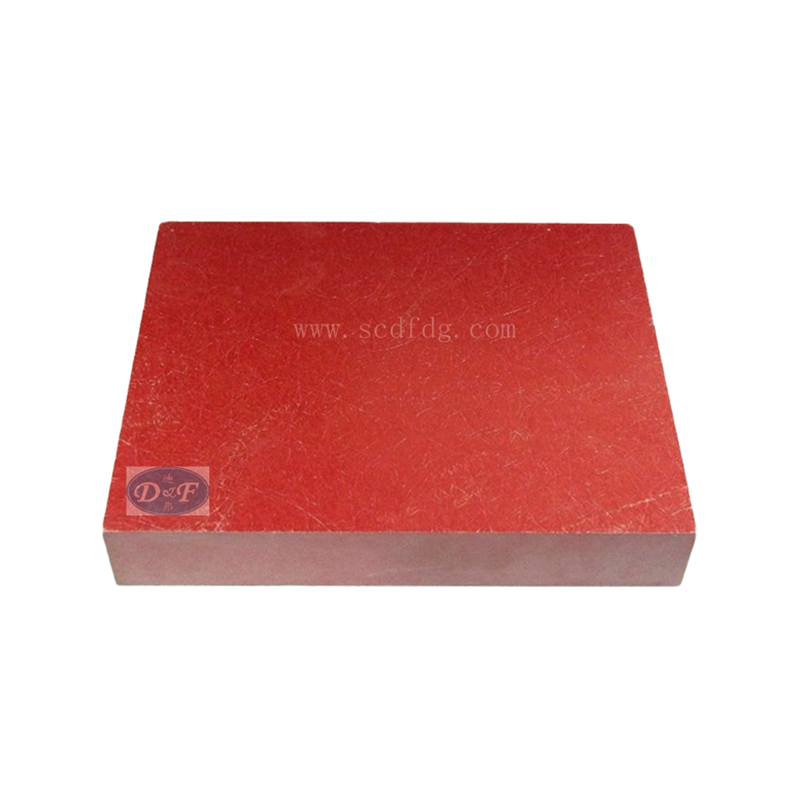

Mefuta e fapaneng ea botenya:2mm--60mm

Boholo ba lakane:1020mm *2010mm, 1000mm *2000mm, 1220mm *2440mm le botenya bo bong bo buisaneng kapa/le boholo

'Mala o ka sehloohong: mebala e khubelu, e tšoeu kapa e meng e buisaneng

Ntle le maqephe a laminated a UPGM, re boetse re hlahisa le ho fana ka maqephe a EPGM 203, boholo ba leqephe bo tšoana le ba GPO-3. 'Mala o mosehla kapa o motala. Ka kopo ikopanye le 'na bakeng sa tlhaiso-leseling e batsi.

Litlhoko tsa Tekheniki

Ponahalo

Bokaholimo ba eona bo lokela ho ba bo bataletseng le bo boreleli, bo se nang matheba, matheba kapa mapetso 'me bo se na liphoso tse ling tse nyane tse kang mengoapo, matheba le mebala e sa lekanang.

T e tloaelehilengho tsikinyeha lemamello

| Botenya bo ipolelang (mm) | Mamello e lumelletsoeng (mm) | Botenya bo ipolelang (mm) | Mamello e lumelletsoeng (mm) | |

| 0.8 | +/-0.23 | 12 | +/-0.90 | |

| 1.0 | +/-0.23 | 14 | +/-1.00 | |

| 2.0 | +/-0.30 | 16 | +/-1.10 | |

| 3.0 | +/-0.35 | 20 | +/-1.30 | |

| 4.0 | +/-0.40 | 25 | +/-1.40 | |

| 5.0 | +/-0.55 | 30 | +/-1.45 | |

| 6.0 | +/-0.60 | 40 | +/-1.55 | |

| 8.0 | +/-0.70 | 50 | +/-1.75 | |

| 10.0 | +/-0.80 | 60 | +/-1.90 | |

| Ela Hloko: Bakeng sa maqephe a botenya bo sa ngolwang a sa thathamiswang tafoleng ena, kheloho e dumelletsweng e tla tshwana le ya botenya bo boholo bo latelang. | ||||

Thepa ea 'mele, ea mechini le ea motlakase

| Matlo | Yuniti | Boleng bo tloaelehileng | Boleng bo tloaelehileng | Mokhoa oa teko | ||

| Botenya | g/cm3 | 1.65~1.95 | 1.8 | GB/T 1033.1-2008 | ||

| (mokhoa oa A) | ||||||

| Ho monya metsi, botenya ba 3mm | % | ≤ 0.2 | 0.16 | ASTM D790-03 | ||

| Matla a ho tenyetseha, a otlolohileng ho laminations (Bolelele) | Boemong bo tloaelehileng | MPa | ≥180 | 235 | ASTM D790-03 | |

| 130℃+/-2℃ | ≥100 | 144 | ||||

| Modulus e flexural, e otlolohileng ho laminations (Bolelele) | Boemong bo tloaelehileng | MPa | - | 1.43 x 104 | ||

| 130℃+/-2℃ | - | 1.10 x 104 | ||||

| Matla a ho tenyetseha, a otlolohileng ho laminations (Bolelele) | Bolelele | MPa | ≥170 | 243 | GB/T 1449-2005 | |

| Tsela e tšekaletseng | ≥150 | 240 | ||||

| Matla a Tšusumetso, a tsamaellanang le li-lamination | KJ/m2 | ≥40 | 83.1 | GB/T 1043.1-2008 | ||

| (Charpy, e sa notlolloa) | ||||||

| Matla a Tšusumetso, a tsamaellanang le li-lamination | J/m | - | 921 | ASTM D256-06 | ||

| (Izod, e sehiloeng) | ||||||

| Matla a tšepe | MPa | ≥150 | 165 | GB/T 1040.2-2006 | ||

| Modulus ea ho tenyetseha ha tensile | MPa | ≥1.5x104 | 1.7 x 104 | |||

| Matla a ho tenyetseha, a tsamaellana le laminations | Bolelele | MPa | ≥55 | 165 | GB/T1447-2005 | |

| Tsela e tšekaletseng | ≥55 | 168 | ||||

| E shebane le li-lamination | MPa | - | 230 | ASTM D695-10 | ||

| Matla a khatello | ||||||

| Matla a dielektrike, a otlolohile ho laminations (ka oli ea transformer ea 25# ho 90℃+/-2℃, teko ea nako e khuts'oane, electrode ea cylindrical ea Φ25mm/Φ75mm) | KV/mm | ≥12 | 135 | IEC60243-1:2013 | ||

| Motlakase oa ho senyeha, o tsamaellanang le li-animation (ka oli ea transformer ea 25# ho 90℃+/-2℃, teko ea nako e khuts'oane, electrode ea poleiti ea Φ130mm/Φ130mm) | KV | ≥35 | >100 | |||

| Tekanyo e amanang le tumello (1MHz) | - | ≤ 4.8 | 4.54 | GB/T 1409-2006 | ||

| Ntho ea ho qhalana ha dielectric (1MHz) | - | ≤ 0.03 | 1.49 x 10-2 | |||

| Khanyetso ea Arc | s | ≥180 | 187 | GB/T 1411-2002 | ||

| Khanyetso ea ho latela | CTI | V | ≥600 | CTI 600 | ||

| Ho feta tekano | GB/T 4207-2012 | |||||

| PTI | ≥600 | PTI 600 | ||||

| Khanyetso ea ho thibela ho ruruha | Boemong bo tloaelehileng | Ω | ≥1.0x1013 | 5.4 x 1014 | GB/T 10064-2006 | |

| (Li-electrode tsa phini e tenya) | Kamora lihora tse 24 ka metsing | ≥1.0x1012 | 2.5 x 1014 | |||

| Ho cha (Mokhoa o otlolohileng) | Sehlopha | V-0 | V-0 | UL94-2013 | ||

| Terata e benyang | - | - | GWIT: 960/3.0 | GB/T5169.13-2006 | ||

| Bothata ba Barcol | - | ≥ 55 | 60 | ASTM D2583-07 | ||

Tlhahlobo, Letšoao, Sephutheloana le Polokelo

1) Sehlopha se seng le se seng se lokela ho lekoa pele se romelwa. Dintho tsa tlhahlobo bakeng sa Teko ya Tlwaelo di tla kenyeletsa Seratswana sa 2.1, 2.2, le Seratswana sa 1 le Seratswana sa 3 sa Tafole ya 6 ho Seratswana sa 2.3. Dintho tse ho Seratswana sa 2.1, 2.2, di lokela ho hlahlojwa ka bonngoe.

2) Maqephe a lokela ho bolokoa sebakeng seo mocheso o seng hodimo ho 40℃, mme a bewe ka ho rapama hodima poleiti ya bethe e bophahamo ba 50mm kapa ho feta. Boloka hole le mollo, mocheso (sesebelisoa sa ho futhumatsa) le letsatsi le tobileng. Nako ya polokelo ya maqephe ke dikgwedi tse 18 ho tloha ka letsatsi leo a tswang fekthering ka lona. Haeba nako ya polokelo e feta dikgwedi tse 18, sehlahiswa le sona se ka sebediswa kamora ho lekoa hore se tshwanelehe.

Litlhaloso le Litlhokomelo tsa ho Sebetsana le ho Sebelisa

1) Lebelo le phahameng le botebo bo bonyenyane ba ho seha di tla sebediswa ha ho sebetswa ka lebaka la ho kganna ha mocheso o fokolang wa maqephe.

2) Ho sebetsa ka mochini le ho seha sehlahisoa sena ho tla ntša lerōle le mosi o mongata. Mehato e loketseng e lokela ho nkoa ho netefatsa hore maemo a lerōle a ka har'a meeli e amohelehang nakong ea ts'ebetso. Ho eletsoa hore moea o kenang ka har'a mosi o tsoang sebakeng seo le ho sebelisa limaske tse loketseng tsa lerōle/likaroloana.

Setifikeiti