Nako e Khutšoanyane ea ho Etella Pele bakeng sa China Epoxy Fiberglass Sheet Type G10, Epgc201, Laminated Sheet G10, Fiberglass Sheet G10, Hgw-2372. DIN-7735

Re se re loketse ho arolelana tsebo ea rona ea ho bapatsa lefats'e ka bophara le ho u khothaletsa lihlahisoa tse loketseng ka litheko tse matla ka ho fetisisa tsa thekiso. Kahoo Lisebelisoa tsa Profi li u fa boleng bo holimo ba chelete 'me re se re loketse ho hlahisa hammoho ka Nako e Khutšoanyane ea Lead bakeng sa China Epoxy Fiberglass Sheet Type G10, Epgc201, Laminated Sheet G10, Fiberglass Sheet G10, Hgw-2372. DIN-7735, Ke feela bakeng sa ho fihlela sehlahisoa sa boleng bo botle ho fihlela tlhoko ea bareki, lihlahisoa tsohle tsa rona li hlahlobiloe ka hloko pele li romelloa.

Re se re loketse ho arolelana tsebo ea rona ea ho bapatsa lefats'e ka bophara le ho u khothaletsa lihlahisoa tse loketseng ka litheko tse phahameng ka ho fetisisa tsa thekiso. Kahoo Profi Tools e u fa boleng bo holimo ba chelete 'me re se re loketse ho hlahisa hammoho le e' ngoe le e 'ngoe kaChaena Epgc202, Sehlopha sa G10 F, Re thehile sistimi e tiileng ea taolo ea boleng. Re na le leano la ho khutlisa le ho fapanyetsana, 'me u ka fapanyetsana matsatsing a 7 kamora ho fumana li-wig haeba li le seteisheneng se secha 'me re fana ka litšebeletso tsa ho lokisa lihlahisoa tsa rona mahala. Ka kopo ikutloe u lokolohile ho ikopanya le rona bakeng sa tlhaiso-leseling e batsi haeba u na le lipotso. Re thabela ho sebetsa bakeng sa moreki e mong le e mong.

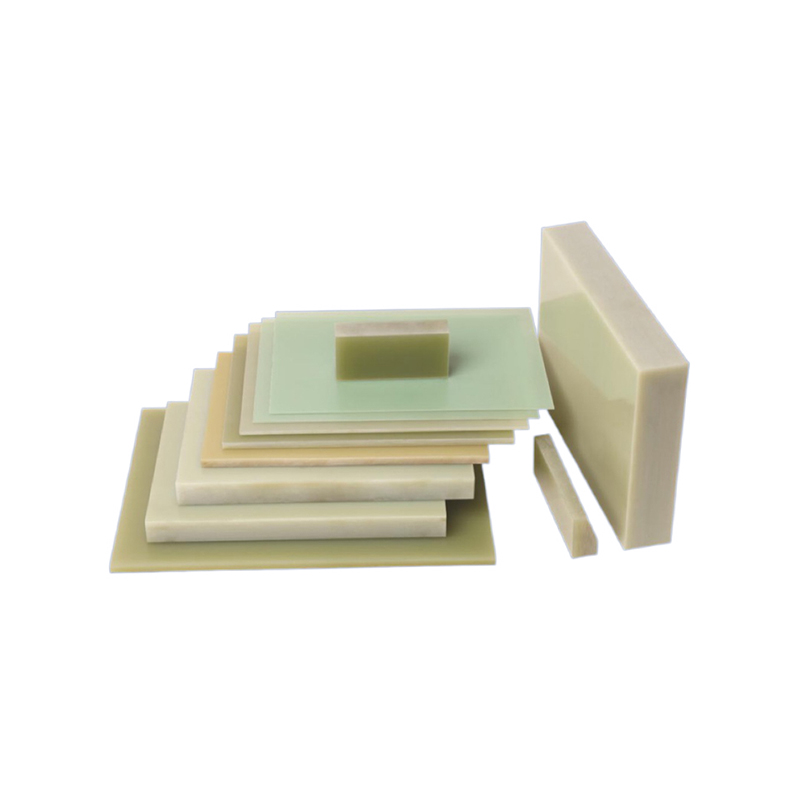

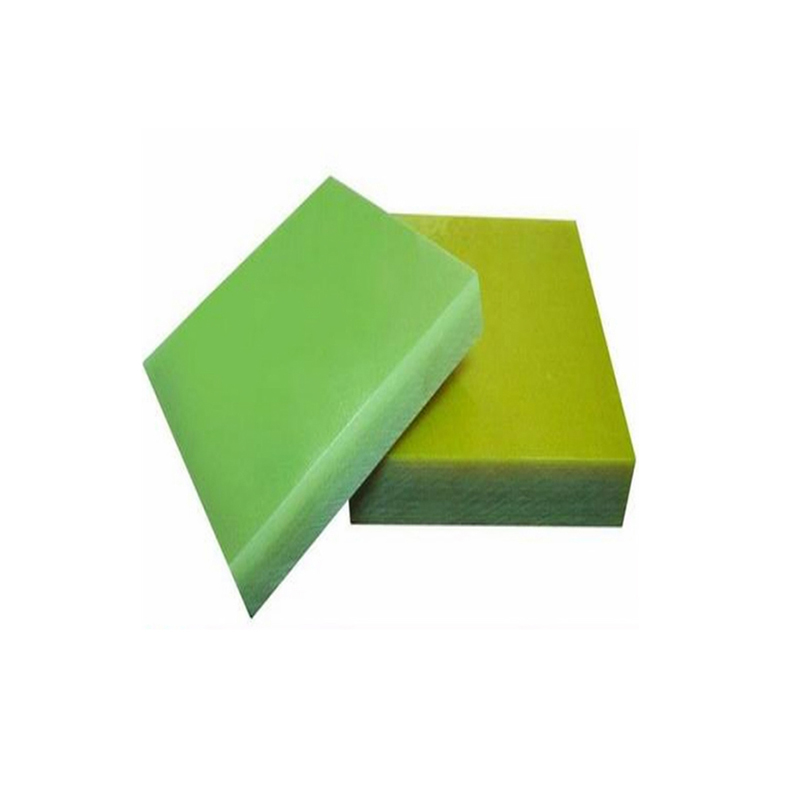

Leqephe le thata la EPGC la Epoxy Glass Cloth le nang le Laminated Sheet le na le lesela la khalase le lohiloeng le tšetsoeng resin ea epoxy thermoseting, le laminated tlas'a mocheso o phahameng le khatello e phahameng. Lesela la khalase le lohiloeng le lokela ho se be le alkali 'me le phekoloe ke silane coupler. Maqephe a EPGC a kenyeletsa EPGC201 (NMEMA G10), EPGC202 (NEMA FR4), EPGC203 (NEMA G11), EPGC204 (NEMA FR5), EPGC306 le EPGC308.

Maqephe a EPGC (sehlopha sa mocheso: B~H), a hlahisitsoe ho latela IEC60893-3-2. Maqephe ana a na le matla a matle a mechini (sekhahla sa ho boloka matla a boemo ba mocheso se ka fihla ho feta 50%) tlas'a mocheso o mahareng kapa boemo ba mocheso, hammoho le thepa e tsitsitseng ea motlakase (khanyetso ea ho thibela mocheso ka mor'a ho qoelisoa e fihla ho 1012Ω) boemong bo phahameng ba mongobo. Hape le ka matla a phahameng a mamello / ho mamella motlakase (ho feta 35kV), ho tsamaellana le lamination. EPGC202, EPGC204 le EPGC306 le tsona li na le thepa e ntle ea ho thibela mollo. Maqephe ana a boetse a fetile tlhahlobo ea lintho tse chefo le tse kotsi (ka Tlaleho ea RoHS).

E sebelisoa e le likarolo tsa sebopeho sa ho thibela ho ruruha ho li-motor tsa motlakase tsa Sehlopha sa BH, lisebelisoa tsa motlakase, tse nang le litlhoko tsa ho hanyetsa malakabe kapa che, kapa lits'ebetso tse ling.

Botenya bo fumanehang:0.30mm ~ 200mm

Boholo ba lakane bo fumanehang:

1500mm*3000mm、1220mm*3000mm、1020mm*3000mm、1020mm*2440mm、1220mm*2440mm、1500mm*2440mm、1000mm*2000mm、1200mm*2000mm le boholo bo bong bo reriloeng.

Tlhophiso le Mofuta oa Maqephe a Epgc

| Lebitso la mofuta | Sesebelisoa le tšobotsi | Sehlopha sa mocheso | |||

| D&F | GB/IEC | NEMA | ba bang | ||

| DF201 | EPGC201 | G10 | Hgw 2372 | Bakeng sa mechini, lisebelisoa tsa motlakase le lielektrone. Ka matla a phahameng tlas'a mocheso o mahareng, khanyetso e ntle ea arc le PTI le CTI e phahameng | B 130℃ |

| DF202 | EPGC202 | FR-4 | Hgw 2372.1,F881 | Ho tšoana le EPGC201, e nang le sethibela-mollo se boletsoeng. | B 130℃ |

| DF202A | — | — | — | E tšoana le DF202, empa e na le matla a phahameng a mechini. | B 130℃ |

| DF203 | EPGC203 | G11 | Hgw2372.4 | Bakeng sa disebediswa tsa mechini, tsa motlakase le dielektrone. Ka matla a hodimo ka tlase ho mocheso o mahareng | F 155℃ |

| DF204 | EPGC204 | FR-5 | Hgw 2372.2 | Ho tšoana le DF203, e nang le sethibela-mollo se boletsoeng. | F 155℃ |

| DF306 | EPGC306 | — | DF336 | E ts'oanang le DF203, e na le khanyetso e ntle ea malakabe, khanyetso ea arc le PTI e phahameng. | F 155℃ |

| DF306A | — | — | — | E tšoana le DF306, empa e na le matla a phahameng a mechini. | F 155℃ |

| DF308 | EPGC308 | — | — | E tšoana le DF203, empa e na le botsitso bo betere ba mocheso. | H 180℃ |

Litlhoko tsa Tekheniki

Ponahalo

Bokaholimo ba lakane bo lokela ho ba bo bataletseng le bo boreleli, bo se nang lipululana tsa moea, makukuno kapa mapetso 'me bo se na liphoso tse ling tse nyane tse kang mengoapo, matheba, jj. Moeli oa lakane o lokela ho ba o hloekileng 'me o se na matheba le mapetso. 'Mala o lokela ho tšoana hantle, empa matheba a 'maloa aa lumelloa.

Botenya bo ikgethang le mamelloYuniti: mm

| Botenya bo ikgethang | Ho kheloha | Botenya ba Nimenal | Ho kheloha |

| 0.5,0.6 0.8,1.0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.15 +/-0.18 +/-0.21 +/-0.25 +/-0.30 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.85 +/-2.10 +/-2.45 +/-2.60 +/-2.80 |

| Litlhaloso: Bakeng sa maqephe a botenya bo sa ngoloang a sa thathamisoang Tafoleng ena, kheloho e lumelletsoeng e tla tšoana le ea botenya bo boholo bo latelang. | |||

Ho Kobeha ha MaqepheYuniti: mm

| Botenya | Ho Kobeha ho Fapoha |

| 3.0~6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 |

Ts'ebetso ea mechini:

Maqephe a lokela ho se be le mapetso le masalla ha ho sebetsoa machining a kang ho saga, ho tjheka, ho loha le ho sila.

Thepa ea 'Mele, ea Mekaniki le ea Dielectric

| Tjhe. | Matlo | Yuniti | EPGC201 | EPGC202 | EPGC203 | ||||

| Boleng bo tloaelehileng | Boleng bo tloaelehileng | Boleng bo tloaelehileng | Boleng bo tloaelehileng | Boleng bo tloaelehileng | Boleng bo tloaelehileng | ||||

| 1 | Ho monya metsi (lakane la 2mm) | mg | ≤20 | 8 | ≤20 | 9 | ≤20 | 9 | |

| 2 | Matla a tenyetsehang | Boemong bo tloaelehileng | MPa | ≥340 | 460 | ≥340 | 500 | ≥340 | 450 |

| (Bolelele) | 155℃+/-2℃ | — | — | — | — | ≥170 | 240 | ||

| 3 | Matla a tshusumetso, a tsamaellanang le di-lamination (Charpy, notch) | kJ/m2 | ≥33 | 53 | ≥33 | 51 | ≥33 | 50 | |

| 4 | Matla a motlakase, a otlolohile ho laminations (ka oli ea transformer ho 90℃+/-2℃) | kV/mm | ≥11.8 | 17 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Matla a motlakase, a tsamaellanang le a lamination (ka oli ea transformer ho 90℃+/-2℃) | kV | ≥35 | 48 | ≥35 | 45 | ≥35 | 45 | |

| 6 | Ntho ea ho qhalana ha dielectric (1MHz) | — | ≤0.04 | 0.02 | ≤0.04 | 0.02 | ≤0.04 | 0.021 | |

| 7 | Dielectric e sa fetoheng (1MHz) | — | ≤5.5 | 4.8 | ≤5.5 | 4.7 | ≤5.5 | 4.7 | |

| 8 | Khanyetso ea selikalikoe | s | — | — | — | 182 | — | 182 | |

| 9 | Khanyetso ea ho latela bopaki (PTI) | V | — | — | — | 600 | — | 600 | |

| 10 | Khanyetso ea ho thibela ho ruruha ka mor'a ho qoelisoa ka metsing | MΩ | ≥5.0×104 | 2.1 x107 | ≥5.0×104 | 1.5 x106 | ≥5.0×104 | 1.1 x107 | |

| 11 | Ho cha | Sehlopha | — | — | V-0 | V-0 | — | — | |

| 12 | Tekanyo ea Mocheso (TI) | — | ≥130 | ≥130 | ≥155 | ||||

| Tjhe. | Matlo | Yuniti | EPGC204 | EPGC306 | EPGC308 | ||||

| Boleng bo tloaelehileng | Boleng bo tloaelehileng | Boleng bo tloaelehileng | Boleng bo tloaelehileng | Boleng bo tloaelehileng | Boleng bo tloaelehileng | ||||

| 1 | Ho monya metsi (2mm) | mg | ≤20 | 11 | ≤20 | 8 | ≤20 | 9 | |

| 2 | Matla a tenyetsehang | Boemong bo tloaelehileng | MPa | ≥340 | 480 | ≥340 | 460 | ≥340 | 500 |

| (Lengwise) | 155℃+/-2℃ | ≥170 | 260 | ≥170 | 280 | — | 270 | ||

| 3 | Matla a tshusumetso, a tsamaellanang le di-lamination (Charpy, notch) | kJ/m2 | ≥33 | 51 | ≥33 | 53 | ≥33 | 52 | |

| 4 | Matla a motlakase, a otlolohile ho laminations (ka oli ea transformer ho 90℃+/-2℃) | kV/mm | ≥11.8 | 16 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Matla a motlakase, a tsamaellanang le a lamination (ka oli ea transformer ho 90℃+/-2℃) | kV | ≥35 | 45 | ≥35 | 48 | ≥35 | 45 | |

| 6 | Ntho ea ho qhalana ha dielectric (1MHz) | — | ≤0.04 | 0.018 | ≤0.04 | 0.02 | ≤0.04 | 0.02 | |

| 7 | Dielectric e sa fetoheng (1MHz) | — | ≤5.5 | 4.7 | ≤5.5 | 4.8 | ≤5.5 | 4.7 | |

| 8 | Khanyetso ea selikalikoe | s | — | — | — | 182 | — | — | |

| 9 | Khanyetso ea ho latela bopaki (PTI) | V | — | — | — | 600 | — | — | |

| 10 | Khanyetso ea ho thibela ho ruruha ka mor'a ho qoelisoa ka metsing | MΩ | ≥5.0×104 | 3.8 x106 | ≥5.0×104 | 1.8 x107 | ≥5.0×104 | 7.1 x106 | |

| 11 | Ho cha | Sehlopha | V-0 | V-0 | V-0 | V-0 | — | — | |

| 12 | Tekanyo ea Mocheso (TI) | — | ≥155 | ≥155 | ≥180 | ||||

Ho paka le ho boloka

Maqephe a lokela ho bolokoa sebakeng seo mocheso o seng hodimo ho 40℃, mme a bewe ka ho rapama hodima poleiti e bolelele ba 50mm kapa ho feta. Boloka hole le mollo, mocheso (sesebelisoa sa ho futhumatsa) le letsatsi le tobileng. Nako ya polokelo ya maqephe ke dikgwedi tse 18 ho tloha ka letsatsi leo a tswang fekthering ka lona. Haeba nako ya polokelo e feta dikgwedi tse 18, sehlahiswa se ka sebediswa hape kamora ho lekoa ho netefatsa hore se a tshwaneleha.

Litlhaloso le Litlhokomelo Bakeng sa Ts'ebeliso

1 Ho sebetsa ka mechine ho tla latela JB/Z141-1979,Mekhoa ea ho etsa mechini ea lihlahisoa tse nang le laminated tse sireletsang mocheso, hobane maqephe a na le phapang ea tlhaho ho tsoa ho tšepe.

2 Lebelo le phahameng le botebo bo bonyenyane ba ho seha di tla sebediswa ha ho sebetswa ka lebaka la ho kganna ha mocheso o fokolang wa maqephe.

3 Ho etsa machining le ho seha sehlahisoa sena ho tla ntša lerōle le mosi o mongata. Mehato e loketseng e lokela ho nkoa ho netefatsa hore maemo a lerōle a ka har'a meeli e amohelehang nakong ea ts'ebetso. Ho eletsoa hore moea o kenang ka har'a mosi o tsoang sebakeng seo le ho sebelisa limaske tse loketseng tsa lerōle/likaroloana.

4 Maqephe a ka tlas'a mongobo ka mor'a ho sebelisoa ka mochini, ho khothaletsoa ho apesa ka ho kenya mocheso o sa senyeheng.

Lisebelisoa tsa Tlhahiso

Sephutheloana sa Maqephe a EPGC

Re se re loketse ho arolelana tsebo ea rona ea ho bapatsa lefats'e ka bophara le ho u khothaletsa lihlahisoa tse loketseng ka litheko tse matla ka ho fetisisa tsa thekiso. Kahoo Lisebelisoa tsa Profi li u fa boleng bo holimo ba chelete 'me re se re loketse ho hlahisa hammoho ka Nako e Khutšoanyane ea Lead bakeng sa China Epoxy Fiberglass Sheet Type G10, Epgc201, Laminated Sheet G10, Fiberglass Sheet G10, Hgw-2372. DIN-7735, Ke feela bakeng sa ho fihlela sehlahisoa sa boleng bo botle ho fihlela tlhoko ea bareki, lihlahisoa tsohle tsa rona li hlahlobiloe ka hloko pele li romelloa.

Nako e Khutšoanyane ea ho EtelaChaena Epgc202, Sehlopha sa G10 F, Re thehile sistimi e tiileng ea taolo ea boleng. Re na le leano la ho khutlisa le ho fapanyetsana, 'me u ka fapanyetsana matsatsing a 7 kamora ho fumana li-wig haeba li le seteisheneng se secha 'me re fana ka litšebeletso tsa ho lokisa lihlahisoa tsa rona mahala. Ka kopo ikutloe u lokolohile ho ikopanya le rona bakeng sa tlhaiso-leseling e batsi haeba u na le lipotso. Re thabela ho sebetsa bakeng sa moreki e mong le e mong.